quarinjection

quarinjection

Quarinjection Ignition

The ignition coil generates spark and the distributor distributes it to each spark plug. The distributor also varies the timing of the spark based on the speed of the engine (via a set of centrifugal weights) and the load / requested speed of the engine (via the vacuum advance).

The ECU will now control the timing of the ignition, so I only need to generate a spark and get it to the right spark plug. Modern EFI no longer uses the mechanical distributor but individual coils to deliver spark. You can use one coil for each plug or one coil for two plugs (wasted spark).

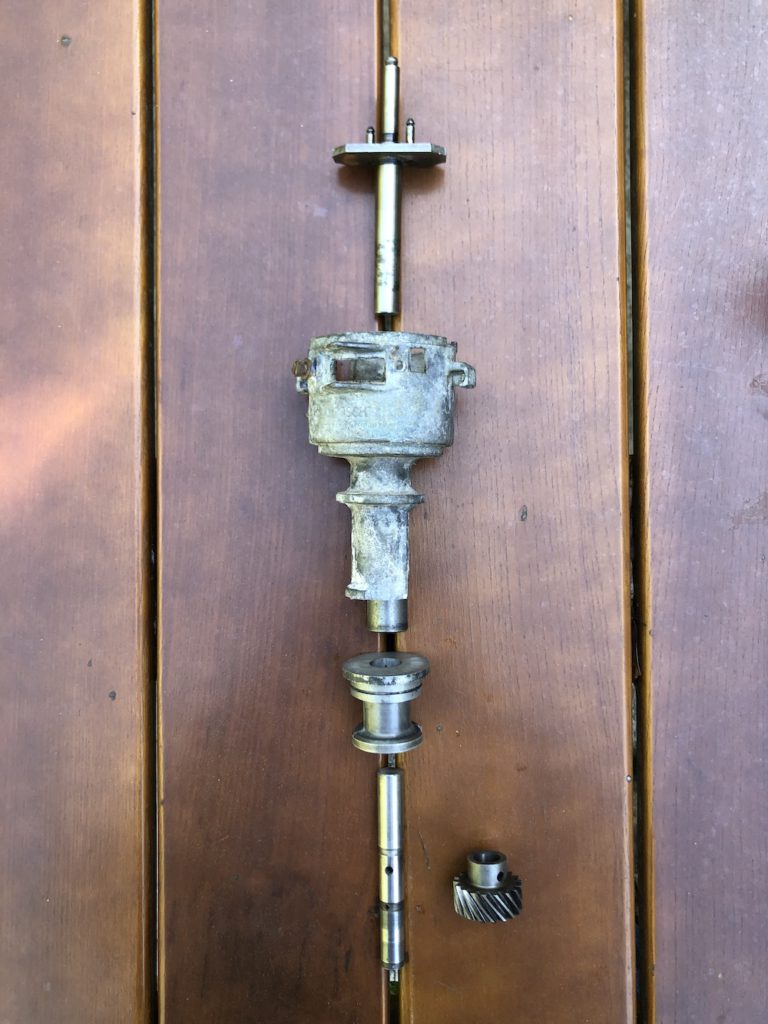

Neutering the distributor: It made sense to put the coil pack in the same place that the old distributor was located but first I had to eliminate the distributor. It can’t just be removed as the shaft also drives the oil pump.

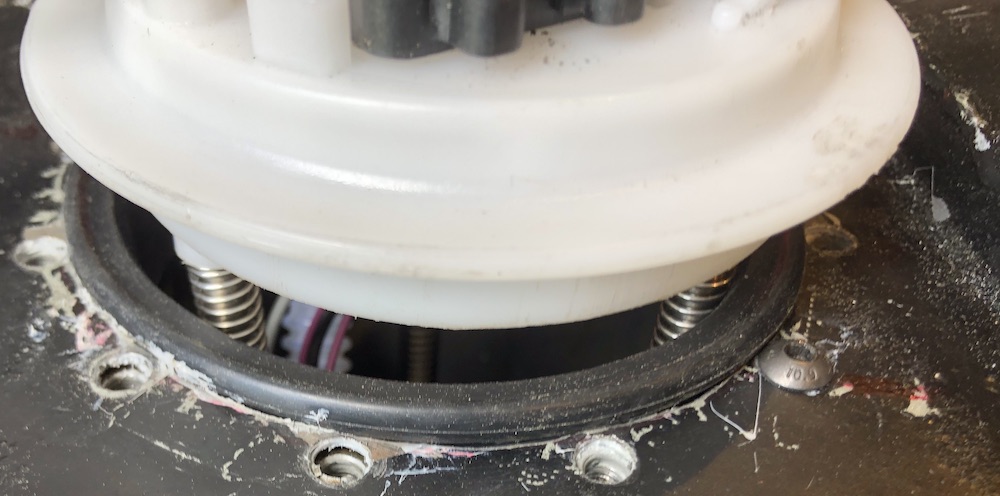

I cut the distributor housing at the flange and shortened the shaft to sit slightly below the surface of the housing. The lower shaft is supported by an oil pressure bearing. The shaft is thrust downward by the gear geometry and there is an axial bearing surface on the gear. There is a bushing in the top of the distributor housing which I felt was unnecessary now that there is little stress on the shortened shaft.

I’ll fabricate a cover and gasket for flange.

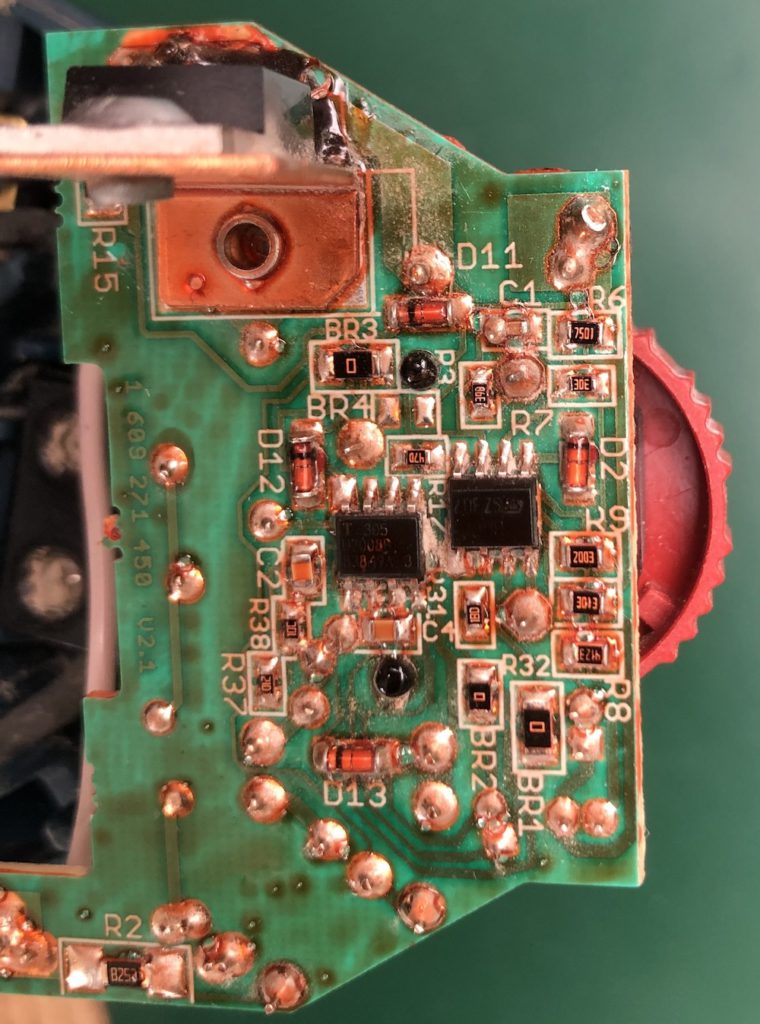

Spark source: I needed a coil that supported 4 cylinders and had a built in igniter. The igniter isolates the high voltage circuit and provides a low voltage interface to the ECU. I chose an ignition pack from 1998-2001 Volkswagen Golf for $15.

I fabricated a mount from sheet steel to locate it near the old distributor location.

Spark delivery: I thought I was going to be able to reuse the ignition wires, but the plugs on the coil are different. The most cost efficient way to replace them was to buy a set of VW/Audi wires ($18) that were compatible with the coil pack and replace the spark plug ends with the correct plug socket ($7). Although there are specialized crimpers, you can get away with some artful work with needle nose pliers. The core is just folded back over the wire.

Ready to be hooked to the ECU!